MANUFACTURING PROCESS

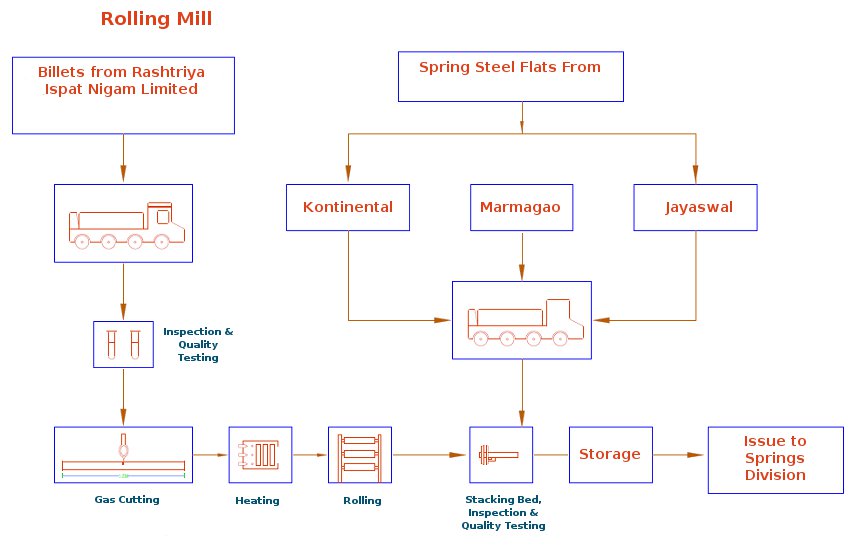

ROLLING MILL

The 75 x 75 mm and 65 x 65 mm billets received from M/s. Rashtriya Ispat Nigam Ltd., are cut into equal length of either 1.2 meter or 1.00meter depending on the cross section of flats to be rolled. These cut billets are then loaded on to the billet re-heating furnace and pushed into the furnace by mechanically operated pusher. These billets travel through the furnace length and gets heated up to a temperature of 1100°c Fully heated billets are then ejected out at the discharge end by an ejector and reach the finishing mill stands and passed through 14 passes to get rolled into a required cross-section. From the final pass, the rolled flat is pushed by a mechanized pusher into a stacking stand. We roll various cross section of flats ranging from 80 mm to45 mm on the width and 15mm to 5 mm on the thickness

SPRING PROCESSING

Apart from springs steel flats rolled in our rolling mill, we also procure flats from M/s. Marmagoa Steel Ltd, Goa, Jayaswal Neco Industries, Raipur and Kontinental Steel Korporation, Jharkand. These flats are delivered to springs division for further processing.

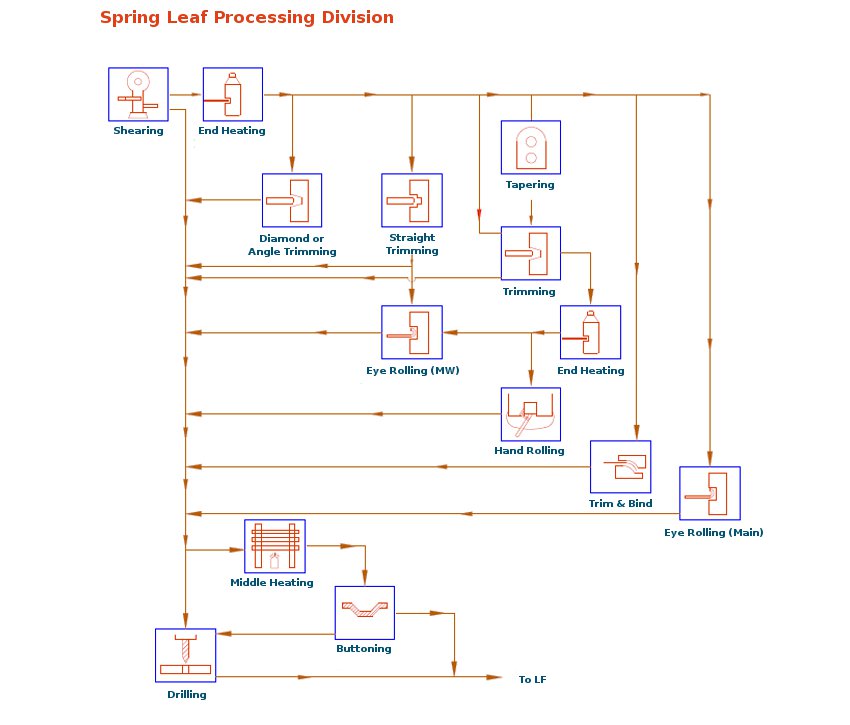

SHEARING

The flats received and stacked are pushed through a flat shearing machine and are cut to required lengths as per the specifications provided.

EYE ROLLING

The main leaf or the top leaf of most of spring assemblies will have a coil to facilitate fitment of assembly to the chassis. In order to provide this coil, the sheared leaves are heated at the ends in an end heating furnace and processed through a three stage eye rolling machine or hydraulic eye rolling machine to form the coil of specified diameter at the ends.

TAPER ROLLING, TRIMMING & HAND ROLLING

This operation is carried out in a taper rolling machine mainly for wrap around leaves (2nd leaf) which are then trimmed in 160 ton power press and hand rolled in a hand rolling machine. These wrap around leaves are fitted below the main leaf and circles around the main leaf coil.

TRIMMING & TRIMMING/BENDING

In order to provide a trapezoidal shape at the ends of the leaves, the sheared leaves are heated in an end heating furnace and processed in 160 ton power press or 63 ton power press where they get trimmed to specified shape. These trimmed leaves normally get fitted below the main leaf or 2nd leaf in a spring assembly.

DIAMOND TRIMMING

The shape of the ends of some of the leaves are trimmed to form a shape resembling surface of a diamond, and hence the name. This is carried out on a 40 ton power press.

All the above operations are carried out after heating leaves in a end heating furnace.

NIBBING/BUTTONING

This operation is carried out in a 40 ton mechanical press where all the leaves including main leaves are heated at the middle of the leaf formed into a button shape with the help of a forging die.

DRILLING

This operation is to drill hole of specified dia at the centre or off centre depending on the specification of the part number.

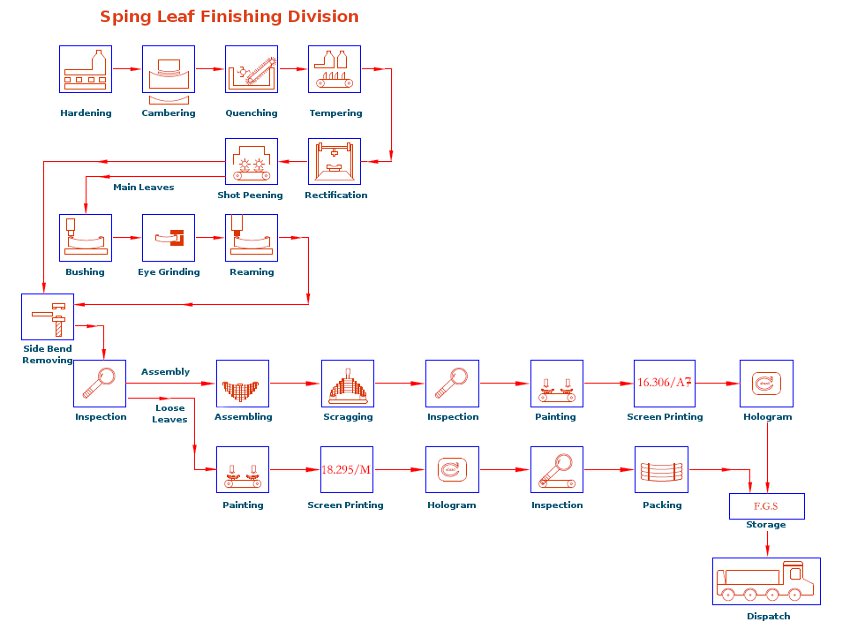

HEAT TREATMENT

The processed spring leaves are heated to a temperature of 825°c to 875°c in a conveyorised or walking beam furnace for about 30 to 35 minutes depending on the cross section and chemical analysis of the leaf. When it is discharged from the furnace, the leaves are cambered to a desired bend in a cambering machine and immediately dropped into a quenching tank filled with quench oil. The leaves travel though the quenching medium for around 15 mts before being taken out. These leaves are stacked in a trolley attached to a electrically heated tempering furnace. The trolley stacked with quenched leaves (hardened) are moved into the tempering furnace chamber where they are heated to a temperature of 450 degree C to 500 degree C and remain in the chamber for 60 minutes after which the trolley is pulled out and cooled. The heat treated leaves are verified for correct hardness in a brinell hardness tester.

RECTIFICATION

The heat treated leaves are subjected for minor camber correction in a screw press to match the specimen leaves of the same part number.

SHOT PEENING

The heat treated and corrected leaves are passed through a shot peening machine where the fine steel shots are hammered on the top surface (tension surface) of the leaf at a high velocity. This operation improves fatigue life of spring leaves and also better surface finish.

We are the only indian company where 100% of the leaves manufactured are shot peened.

BUSHING, REAMING & GRINDING

All the spring main leaves are inserted with mild steel bushes at both ends by a hydraulic bush pressing machine. Inner diameter of the bush is reamed to clear any distortion created while fitting the bush. Subsequently the sides of eyes are ground in an eye grinding machine to enable the leaf to fit freely into the shackle of the vehicle chasis.

Finally before the leaves are sent for painting and bundling, they are checked for side bend and corrected in a hydraulic side bend correction machine.

ASSEMBLY

The company manufactures and supplies assemblies on specific order from customers. For this purposed the required leaves are collected after shot peening. The camber of these leaves are modified in a screw press for specific assembly camber. Clip leaves of the assembly are fitted clips and assembled along with the other leaves in a hydraulic assembly table.

These assemblies are subjected to scragging in a scragging machine where it is deflected thrice in succession. This is to make the assembled leaves to set perfectly without any gap between them. These assemblies are painted before dispatch.